Signal Integrity Pcb Designers

What is the PCB Fabrication service? Our PCB fabrication service involves the manufacture of bare PCBs to your exact design needs and specifications. We’re uniquely connected to our sister company, PCB Train. Together, we fabricate more different types of printed circuit boards per year than any other UK manufacturer. Our unique relationship with PCB Train allows us huge flexibility over order scales. We can make large numbers of small-batch PCBs extremely efficiently and at very low cost.

These savings are passed on to you, so you can enjoy receiving quality circuit boards at an very reasonable price. We have over 50 years experience in the PCB Fabrication field. We use this hard earned expertise to give our customers the best products possible. However, we’re also efficient and flexible in terms of delivery lead times. These lead times can range from a mere 24 hours up to 6 weeks according to your needs. For large production runs we distribute PCBs manufactured by our international manufacturing partners. However, our pre-production PCBs are frequently manufactured in the UK, pending the arrival of production supplies from our partners.

This recycling information guide provides you the information on our service centers. Benq projector drivers windows 10. Recognizing the importance of environmental protection and assigning itself the responsibility of protecting the global environment, BenQ has endeavored, and will steadily continue to endeavor, to construct recycling systems around the world so as to collect and recycle the used BenQ products from our customers. Please see the following list to contact the center in your area, and our service centers will assist you in managing your used BenQ products.

Our entire manufacturing process is overseen and managed so that only one tooling charge is applied. Each product is quality checked in the UK and deliveries are consistently completed on schedule. For our PCB fabrication service we have a large number of available base materials. Those available include; FR4, Polyimide and PTFE. Layer counts encompass single sided, all the way up to 12 layers.

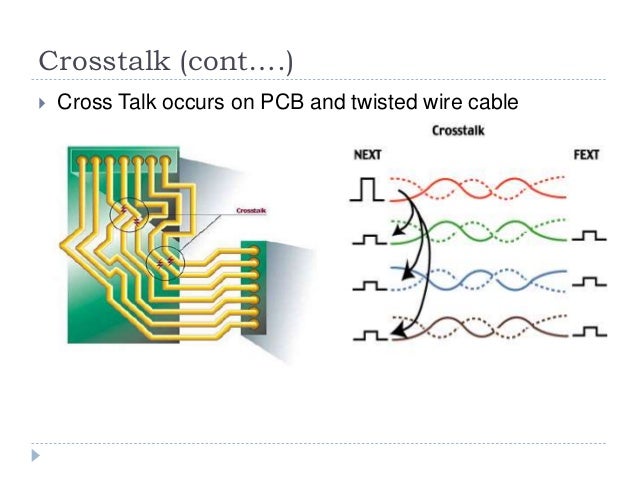

Signal Integrity (SI) The losses associated with PCB transmission lines constitute an important topic in area of high-speed simulation/design and signal integrity. Learn about Signal Integrity and Circuit Board Design Considerations and how to solve common problems.

We offer a wide range of solder resist and legend colours. Finishes available are immersion silver, immersion gold over electroless nickel, Hot Air Solder Level, both lead-free and leaded. Who uses the service?

To reduce signal integrity problems in a PCB design is important to follow some simple printed circuit board design rules to minimize these problems.

Signal Integrity Pcb Design

Our PCB fabrication customers could be anyone who requires a reliable supplier of PCBs. We attract those who appreciate experienced manufacturing and a high quality end product. Our customers may be end users, development engineers, researchers, or contract manufacturers.

Our clients also value local sourcing, confidentiality and good communications. We are happy to provide this.

No quantity is to small and no delivery is ever too fast for us. What are the benefits to users of this service? We offer you competitive pricing, reliable deliveries, good quality and excellent technical support. We have a wealth of experience, having manufactured PCBs for over 60 years.

We are the only UK PCB manufacturer to provide a complete electronic manufacturing service. This includes bare PCB manufacture, electronic assembly, component procurement, and solder paste screen cutting. Our integrated approach, along with the fact that 95% of our manufacturing takes place in-house, means that we take complete responsibility for the quality of your PCB fabrication and electronic assembly.

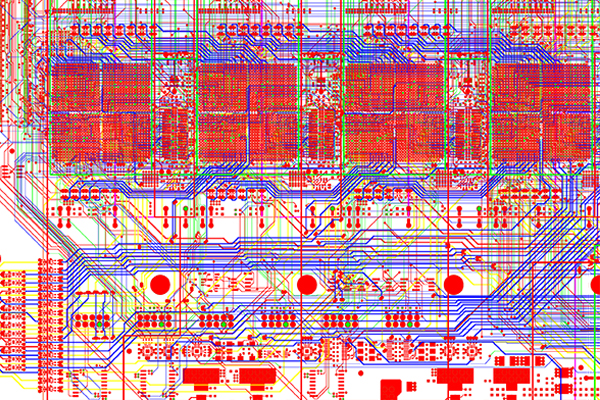

What technology and machinery are used for this service? All our technology and machinery is state-of-the-art. Front-end tooling is performed with the latest CADCAM software tools, with complete design rule checking. We use modern manufacturing technology, such as laser direct imaging, whereby the intermediate photographic process is eliminated. Each FR4 panel is laser scanned to image the tracking pattern. PCBs are drilled on automatic load and unload drilling machines.

Plating and etching are processed on automatic lines to minimise manual handling. Legends are printed with digital ink-jet machines. Electrical tests are performed by automated machines. View our extensive PCB fabrication plant list. Take a through the processes required to fabricate and assemble printed circuit boards.

Signal Integrity TUTORIAL This tutorial is intended for printed circuit board designers who wish to get an insight into the design of High Speed Digital PCBs. INTRODUCTION High Speed PCB Design referes to the techniques that must be followed in order for a circuit to function properly when the edge rate of the signal is high. The failure in high speed digital circuit may or may not be readily reproducible.

They are sometimes difficult to diagnose and reproduce. So care must be taken at the design stage itself. This tutorial is for the PCB Designers who do not have advance course in Circuit Design, High Speed PCB Design or Wave propogation and Electromagnetic theories. It is for those who would like to get enough knowledge that will enable them design a high speed cicuit with reasonable accuracy. The examples of the High Speed Bus design include DDR Bus, HyperTransport Bus, DDR2 Bus, USB 2.0, SATA, PCI Express, PCI. High Speed Design Techniques must be applied to these Bus to ensure proper and reliable operation. The concept of Setup and Hold time and their relation to the length matching will be introduced in the beginning of the tutorial.

The Noise in the Power Supply and its analysis also come into the preview of the High Speed Digital Design and will be covered in this tutorial. We will also explore how and why to add a multilayer PCB. We will analyse common stack up. We will explore the need of the controlled impedance and will try to understand how to acheive it. We will breifly understand the simulation and will try to explore some common platforms and tools that are used for simulations. If you like this tutorial, you may like to. You may also check it on amazon, if is available.